Watch the Samsung 421

ETEMCO's Surface Mount Department is beautifully equipped with Samsung 421 Placement Machines, MPM and SMT Solder Paste Printers, and Electrovert OmniES 7 and Heller Reflow Ovens. Our experienced surface mount technicians operate this equipment with skill, accuracy, and attention to detail, ensuring that your product will be of top quality, within budget, and on schedule.

Surface mount capabilities support:

Watch the Speedline Vectra 2ES Wave Solder

ACE KISS-103 Selective Solder

Although much of the electronic manufacturing industry has migrated toward surface mount technology, there is still a significant need for accurate, effective thru-hole electronic assembly. ETEMCO is fortunate to have a very talented team of assemblers that complete this task either semi-automatically, using our Contact Systems CS400 Component Locator machines, or by using manual techniques. All electronic assembly and soldering is performed to meet or exceed IPC-610 workmanship criteria.

RoHS and Lead Based Through Hole soldering is performed accurately and effectively either by hand or with our ACE K.I.S.S 103 Selective Solder or Speedline Vectra 2ES Wave Solder Machines.

Austin American NanoJet Aqueous Cleaner

Another trend in the electronic manufacturing industry is a shift toward no-clean solder fluxes – and many of our customers have chosen to go that direction. However, many customers, and many applications still require the assembled printed circuit boards to be cleaned of all flux residue. Our Austin American NanoJet Aqueous Cleaner, with a DI Closed Loop System, completes this task perfectly.

As electronic components continue to get smaller and smaller and assemblies continue to become more complex, the ability of the human eye to visually inspect workmanship becomes more difficult. Etemco has addressed this challenge with the addition of AOI and X-Ray capability. Our Mirtec MV-3L Automatic Optical Inspection System features five 10 Megapixel cameras, multiple lighting options, laser based co-planarity inspection, and leading edge algorithms. These features render a vivid and accurate representation of the unit being inspected; verifying that the correct components are properly oriented, installed in the correct location, and soldered to IPC workmanship expectations. The Scienscope X-Scope 1800, in standard or oblique view, allows the operator to inspect BGA soldering to verify IPC compliance. The machine's analysis tools evaluate solder joints for proper reflow, voiding, and circularity.

Watch the Nordson Asymtek C-341

Many of the assemblies that ETEMCO produces are ultimately deployed into harsh environments. Thus, many of our customers require their printed circuit board assemblies to be conformal coated. To address this growing need, ETEMCO has expanded our capabilities by adding a Nordson Asymtek C-341 conformal coating machine to our factory. The C-341 is extremely accurate and efficient, producing a very cost effective conformal coating solution.

If automation does not fit your requirement, then ETEMCO technicians will prepare and coat your products by hand.

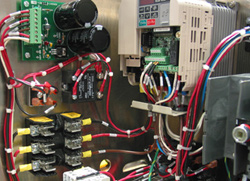

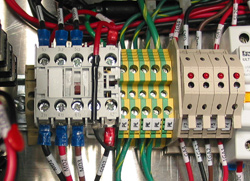

ETEMCO provides more than just electronic assembly services. Many of our customers turn over the entire manufacturing of their product, including not only the printed circuit board and wiring harness assembly but also the installation of these subassemblies into a product housing or chassis.